Delicate Lamination makes design tangible.

We are pleased to support you in your project and find the optimal production method.

However, lamination is not only an optical and tactile highlight; it also has a significant impact on the material. Through lamination, it is possible to produce high grammages, and exciting effects can be achieved by laminating different papers, such as glossy and matte. When it comes to the number of laminated layers, there is hardly any limit upwards, depending on the material and size of the product.

Yet, lamination is more than just refinement. Often, it serves a purpose. For example, the unwanted impression of an embossment on the back can be concealed through an additional lamination. Learn more about embossing here.

| from our commitment to quality |

| from our passion for paper |

| from our enthusiasm for new challenges |

| from our punctuality |

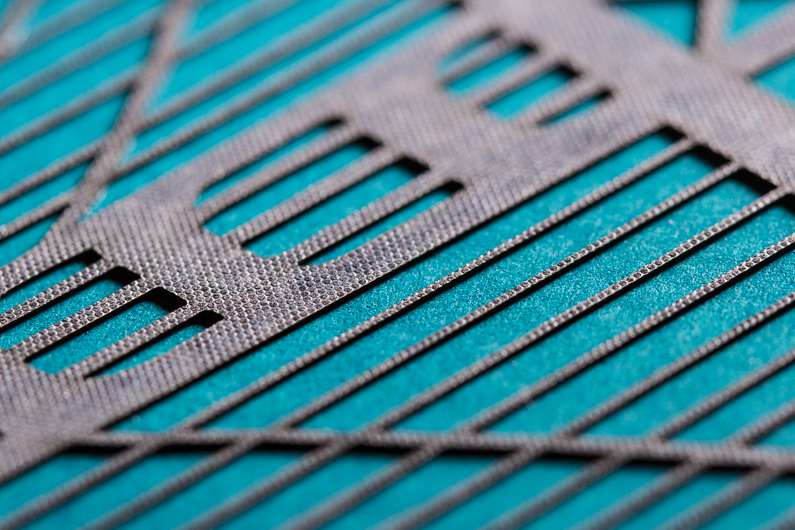

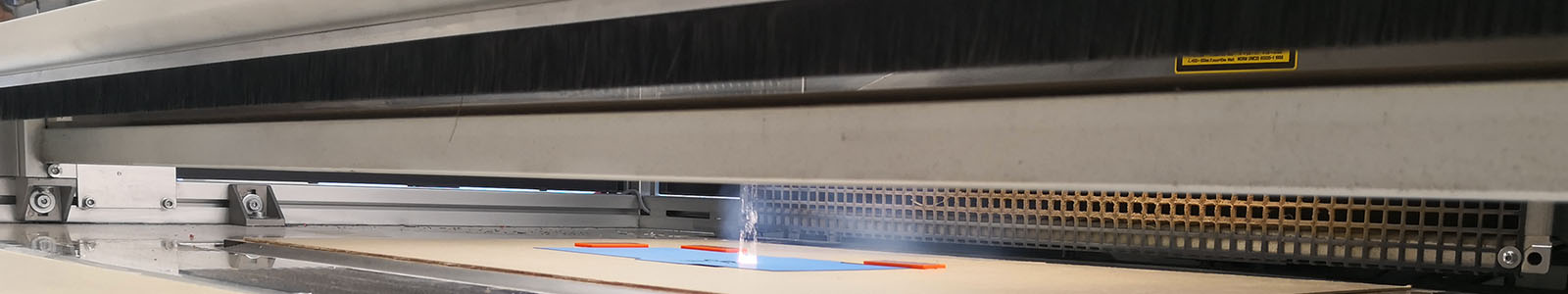

There are many ways to enhance paper noticeably. For example, with embossing, die-cutting (kiss-cut), or laser engraving.

Learn more about our portfolio.

Continue with services