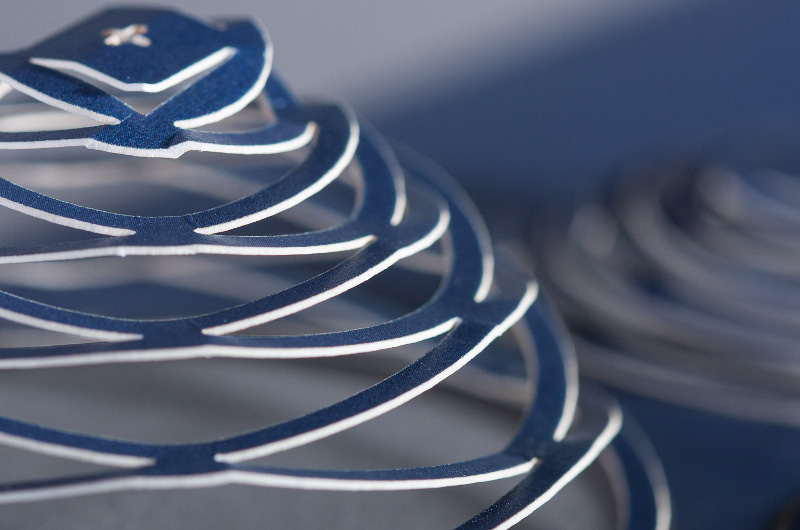

Whether used independently or in combination with other refinement options,

fascinating products are created with laser-cutting.

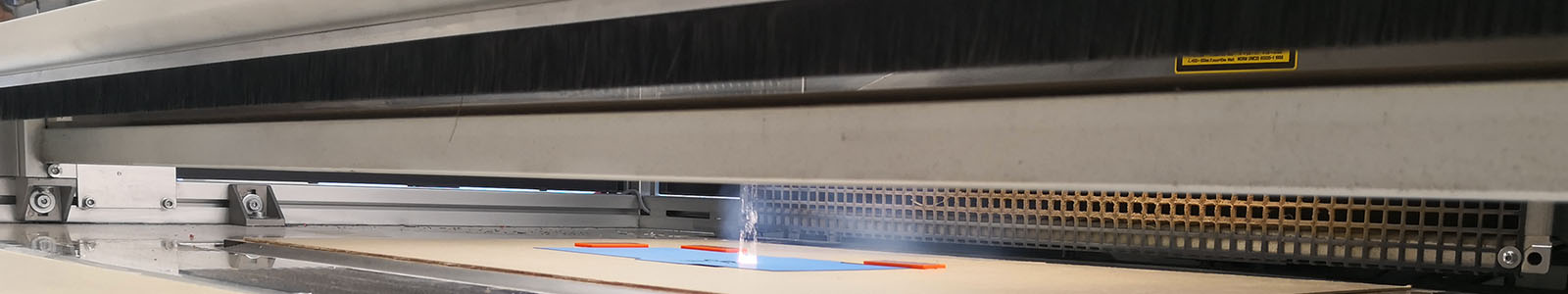

Laser cutting has become an affordable method of print enhancement. The rapid precision cutting with lasers makes it cost-effective for producing individual pieces, small print runs, and intricate contours. Since no die is required, we can react even faster and produce personalized items.

The more intricate the designs, the more stable the paper or desired material should be for laser cutting. Colored natural papers, for example, are particularly suitable for smoke-free laser die-cutting. Coated papers, due to their non-flammable mineral content, tend to exhibit stronger discoloration. With colored paper, these traces are minimized. To ensure your product precisely meets your expectations, we always recommend conducting a material test in advance.

| from more than 10 years of experience in the field of laser refinement |

| from various laser systems tailored to diverse requirements |

| from a well-trained, highly motivated team |

| from our enthusiasm for tackling new challenges |

According to your individual preferences and requirements, a wide range of materials can be cut using laser technology. Examples include cardboard, fabric, textiles, plastics, or leather. Laser cutting is also capable of processing materials such as stone, glass, wood, and various synthetic substances. Find more information about the diversity of materials suitable for laser cutting here.

Laser cutting allows for the realization of almost any desired outlines and motifs, even those that are highly complex. Designs are cut with absolute precision, resulting in excellent edge sharpness. It is possible to achieve both two-dimensional and three-dimensional contours.

The short setup time and fast cutting capabilities of lasers provide a significant advantage. Laser cutting becomes economically viable even for low quantities compared to traditional die-cutting methods. This enables the production of exclusive small batches as well as large industrial runs. Additionally, customized individual pieces can be produced according to your specific requirements. Since no die is required, orders are processed quickly.

Laser cutting and engraving are increasingly popular in the realms of recycling and upcycling. Various recycled materials can be not only cut or engraved but also enhanced or repurposed through laser processing.

In addition to Laser Cut, there are various other applications for our lasers.

For laser refinement