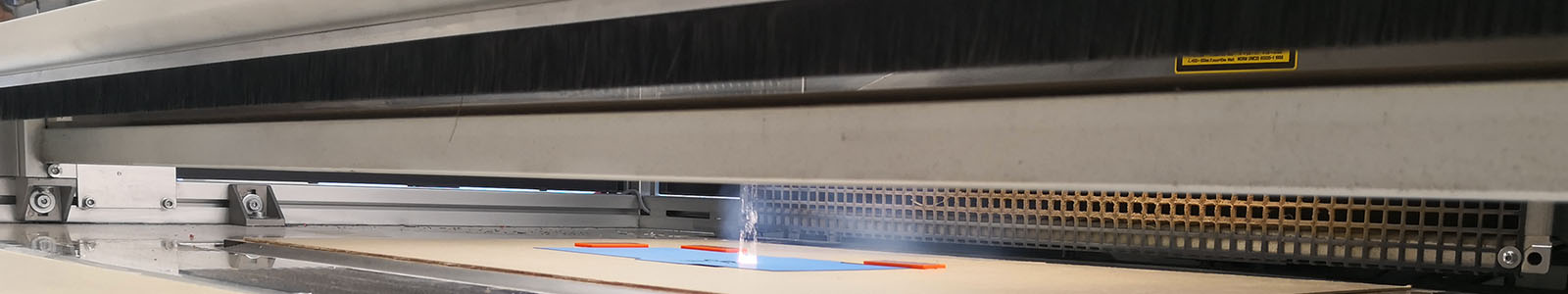

For optimal laser-cut results, crucial aspects need to be considered during data creation. All cutting lines should be vectorized and kept simple. Double lines (multiple identical cuts on top of each other) not only increase processing time and, consequently, the unit price but also result in more smoke residues. Additionally, it's important to ensure that the motifs are not too delicate to minimize the risk of tearing. In the attached gallery, you will find graphics for illustration.