SUITABLE FOR ANY QUANTITY

LASER PERFORATION -

PROCESSING & FINISHING

LASER PERFORATION - COST-EFFECTIVE WITHOUT TOOLS

Using a focused laser beam, small holes or slits are precisely cut into the material at desired intervals. Laser perforation is suitable for both further processing and enhancing traditional printed products.

Especially for small print runs or personalized products, the use of laser technology is worthwhile for all conceivable perforations. Since laser perforation does not require tools and setup times are comparatively short, we can quickly and flexibly respond to your request and economically implement it even for small print runs.

Cardboard, packaging, mailings, letterhead, or folders can be easily perforated with the laser. Additionally, laser perforation provides tamper-evident features on documents and labels. Laser perforation is also suitable as a separation line, as seen in tickets, response letters, or similar applications.

LASER PERFORATION BY STIGLER

STIGLER REFERENCES

Design and Functionality

Laser perforation offers a wide range of application possibilities.

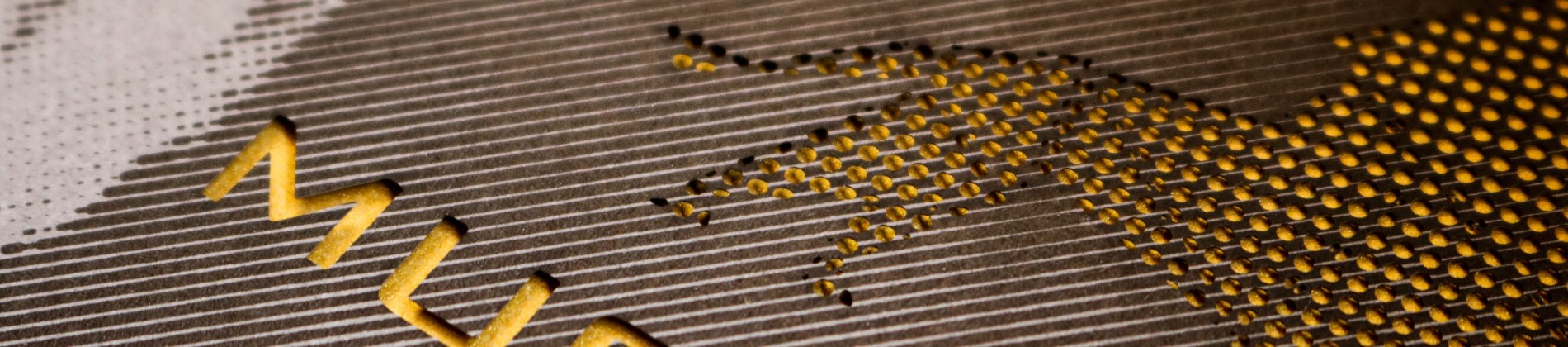

In addition to further processing, laser perforation can also be applied for design purposes. For example, micro-holes can be used to create interesting halftone images or achieve a transparent effect in fonts.

We would be pleased to conduct tests with your materials. This way, we can perfectly align the file and material, ensuring the desired effect of laser perforation is achieved.

PERFORATION FROM THE PROFESSIONAL - YOUR ADVANTAGES

| You will receive comprehensive consultation. |

| You will have a dedicated contact for your project. |

| Our professionals leverage their extensive experience. |

| We prioritize the highest quality standards. |

LASER PERFORATION IN DIFFERENT MATERIALS

For laser perforation, various materials are suitable, including but not limited to paper, cardboard, textiles, thin plastics, foils, and more.

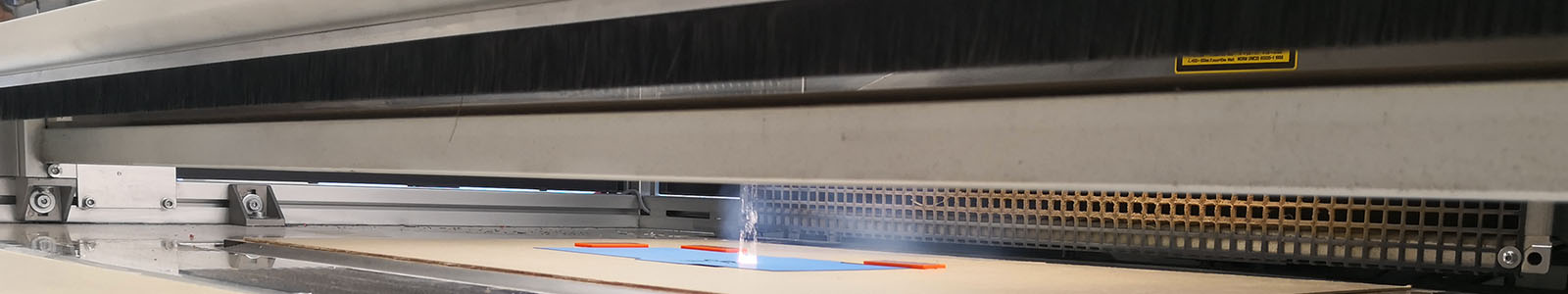

After data creation, a material test is conducted. During this process, the settings of the system, such as speed, power, as well as air supply and exhaust, are optimized. For production, the material is individually placed into the laser system and perforated.

- ADVANTAGES OF LASER PERFORATION

The laser enables precise perforation of the material with very small holes or cuts. The shape, size, and distribution of the holes can be precisely tailored to the specific requirements of the intended application. Since no tools are required, we can respond promptly to changed requirements and specifications. Another advantage, especially with synthetic textiles, is that the cut edge is fused by the heat of the laser beam, preventing fraying of the material.

DIFFERENCE BETWEEN LASER PERFORATION AND PUNCHED PERFORATION

In laser perforation, both slits and round or differently shaped holes are possible and can be combined in a product and changed on short notice.

For punched perforations, die-cut forms with perforation blades are needed. In this case, only slits of varying lengths and distances are possible. Round perforation holes, as seen, for example, in stamps, are punched on special machines with upper and lower blades.

FREQUENTLY ASKED QUESTIONS ABOUT LASER PERFORATION

WHAT IS LASER PERFORATION?

Laser perforation involves using a laser beam to create tiny holes or cuts in the material. Often employed for purely functional purposes, such as fold or tear lines, laser perforation can also be utilized as a design element to create rasterized images or translucent typography through micro-holes.

WHAT IS THE DIFFERENCE BETWEEN LASER PERFORATION AND LASER ENGRAVING?

With laser perforation, the material is cut through in tiny holes or incisions, while laser engraving involves the superficial removal of material. Depending on the material, engraving can occur at various depths, allowing for the creation of three-dimensional views. To get the optimal results while laser-cutting & -engraving it´s necessary to use the right files, visit here to learn everything you need to know about file-formats.

WHAT IS LASER PERFORATION USED FOR?

- A fold perforation facilitates easy and quick folding.

- In packaging, the small holes enable air exchange, making the packaging breathable through laser perforation.

- Used as an unconventional design element for lettering or logos, laser perforation can create exclusive letterheads and envelopes.

- In flyers, folders, or brochures, semi-transparent openings created by laser perforation can emphasize essential elements.

WHAT OTHER REFINEMENT OPTIONS ARE AVAILABLE?

Get inspired by our possibilities.

To our services