Here you can find a small selection of engraved products.

Moreover, there are countless possibilities to implement your desires in design and functionality with laser engraving.

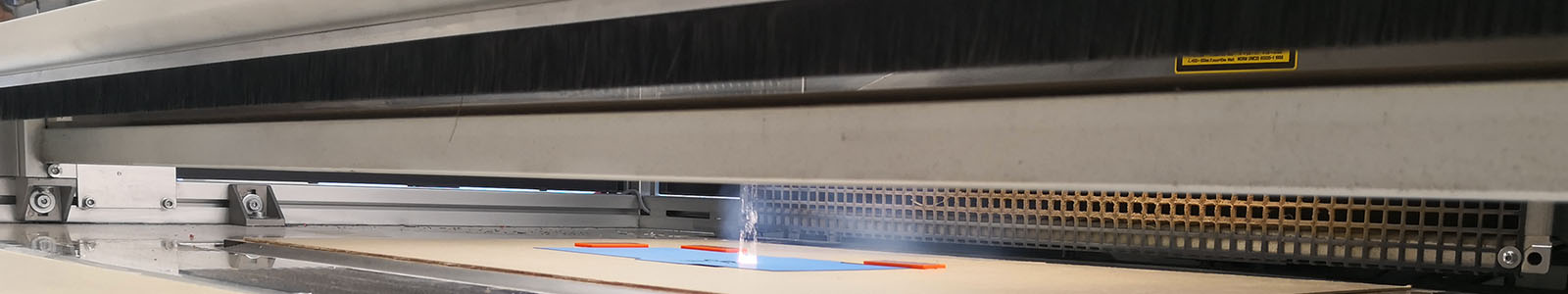

In addition to laser cutting and perforation, the use of laser technology also allows for the engraving of materials. Texts, graphics, images, and photos can be burned into the surfaces of various materials. Modern laser engraving offers significantly expanded possibilities compared to traditional embossing and continues to gain popularity.

Laser technology allows for the engraving of three-dimensional motifs. The laser beam used causes material ablation. To execute the 3D designs, material is removed through heating in different layers. The back remains untouched and can be used or processed differently if needed.

Since laser engravings can be executed in three dimensions, the motifs can be felt. This provides an impressive experience, both visually and haptically. Laser engravings are often characterized by their elegant appearance, frequently astonishing the observer.

| Various laser systems for different requirements |

| Extensive technical expertise through years of experience |

| Creative interest and active support for new projects |

| Swift response time due to production in Kirchheim near Munich |

With the laser beam, engraving is possible on nearly every material (further information on the variety of materials in laser refinement). Your wishes and ideas are almost limitless. Paper, cardboard, stone, glass, wood, metal, synthetic materials, and much more can be engraved with the laser.

However, it's important to note that each material reacts differently to laser processing. Color changes may occur, often accompanied by appealing optical effects. It is advisable to conduct a material test. Multiple material tests may also be useful to gradually find the suitable material for a product that meets your expectations.

Depending on the specific requirements of different materials, different laser systems are used to perform the engravings. It is also important to adjust the parameters of the laser beam according to the material being processed.

A significant advantage of laser engraving is that any quantity can be realized. From individual pieces and exclusive small series to industrial large runs, you can commission it all. Due to the short setup time and the rapid operation of the laser, it is possible to produce economically viable quantities even at very low production volumes.

The laser makes it possible to engrave almost any design you desire, even if the motifs, logos, or lettering are very complex or delicate. The engravings are executed with uncompromising precision and impress with extremely sharp contours.

There are two types of laser engraving: vector engraving and raster engraving. Vector engraving is suitable for monochromatic logos and lettering without color gradients. Images (such as portrait photos) and logos with color gradients can be raster engraved.

Similar to digital printing, it is easy to customize data in laser engraving. Therefore, you can benefit from the possibility of serially personalized laser engraving. For example, it is possible to engrave products with names specific to each individual.

In addition to using laser engravings as decorative elements, laser marking is of great importance. The applications range from labels and signs to markings for technical equipment in various fields, from medical technology to machinery and automotive manufacturing. Moreover, laser marking is perfect for promotional items.

Laser marking offers the advantage of being absolutely resistant to abrasion and can be used on non-flat materials. Beyond marking on curved surfaces, it can also handle other requirements that are difficult to implement with conventional methods. For instance, round writing can be easily implemented through laser marking. The laser can also be used for delicate laser cutting.

Upcycling is a growing trend. In this special form of recycling, materials and products intended for recycling are upgraded. The benefits of lasers can be perfectly showcased, as almost any desired material can be engraved. Your imagination knows hardly any bounds when it comes to making seemingly useless or worthless things attractive and giving them a new purpose.

Tangible effects can, for example, be achieved through embossing or delicate lamination.

For further refinement methods